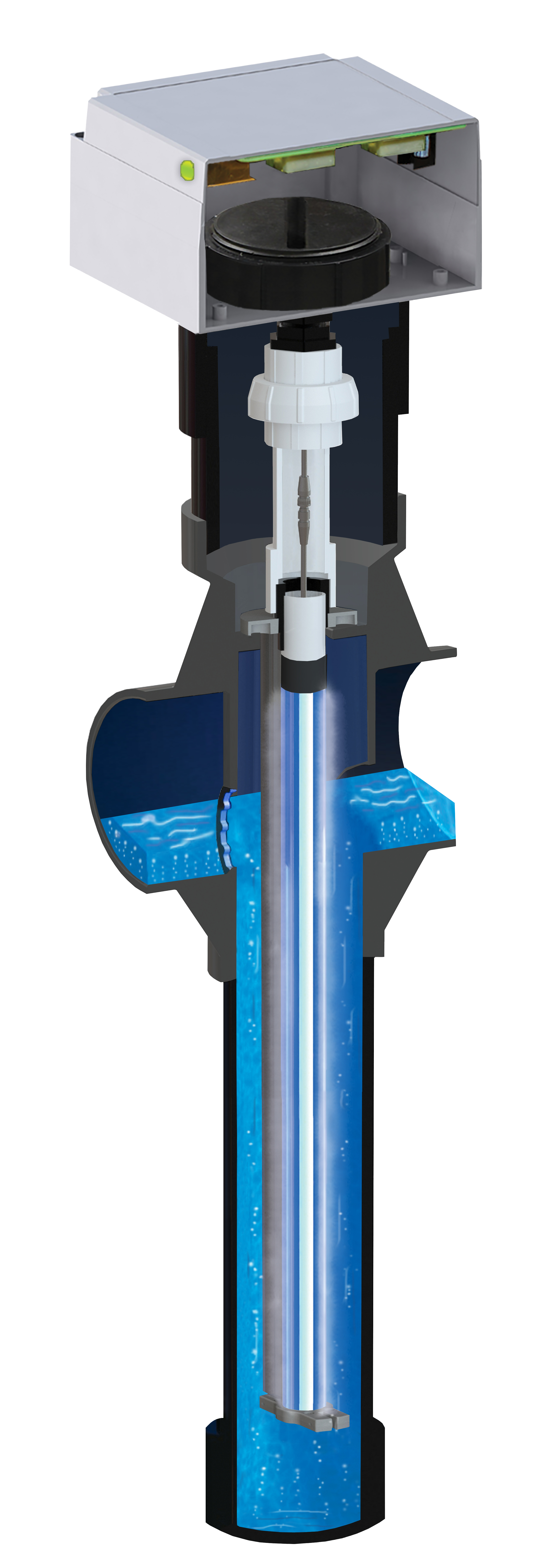

Ultraviolet disinfection of the treated effluent ensures the protection of the environment for direct discharge application or disposal by means of spray irrigation. The Model AT 1500 Ultraviolet (UV) disinfection system provides

reliable treatment without chemical addition. The Model AT 1500 UV disinfection system reduces harmful pathogenic bacteria levels to below recreational water quality standards, particularly with the high quality effluent provided by Singulair treatment systems. The compact design of the system minimizes the amount of excavation required making installation quick and easy. Ultraviolet disinfection is routinely used in ecologically sensitive areas where residuals from chemical disinfection could possibly create problems in the receiving environment.

The Model AT 1500 UV disinfection system is equipped with an internal current sensing circuit that continuously monitors the performance of the UV lamp. This self-diagnostic feature monitors the current that is used by the UV lamp. If the ultraviolet lamp output drops below an acceptable level for proper disinfection, the alarm circuit will turn “off” the green LED located on the outside of the control center and generate an alarm signal. If the disinfection system is connected to a Service Pro control center, the service provider is immediately notified of the alarm condition and a UV disinfection alarm code is registered in the service history database.

All electrical components are contained in a NEMA 6 weatherproof enclosure. The lighting ballast is also contained in the electrical enclosure to assure maximum life. For safety, a power interlock switch is included to automatically de-energize the system during service and routine maintenance.

UPDATE:

After months of frustration with Quality Control and customer support, GTS made the decision to no longer carry Longwave Products. We will update this page more completely in the near future to reflect our replacement: the Norweco AT-1500. The product is similar to Salcor’s, but they’ve made several improvements. Specifically:

- The Teflon cover isn’t a ‘bag’, it’s sprayed onto the quartz tube; no more water between the Teflon and quartz.

- The electrical box is a huge improvement. The top/bottom mate with a seal in between and the halves are secured by captured quart-turn fasteners; no more damaged/lost fiber seals nor over-tightened screws stripping out or creating gaps between the corners.

- The lamp connection is a Molex-style threaded connector, rather than a too-short boot with pins; no more lamps falling out, corroded connections, etc.

- The frame fits inside the ABS housing much better. The Salcor unit was sometimes REALLY tight, with apparently wide tolerances, so it could be difficult to remove for service.

- It’s a much more professional-looking, high-quality product.

One of the primary benefits for former Salcor/Longwave users is that the Norweco components will work inside the Salcor housing, so service providers don’t have to dig or re-plumb anything. The trade-off is that all the parts have to replaced – the Electrical Sub-Assembly (or Control Center, per Norweco terminology), the quartz frame and the lamp. They aren’t interchangeable individually, but once all the parts are Norweco, any further replacements can be done piece-by-piece.